Rare earth magnets and ceramic magnets are both types of permanent magnets. Together they make up over 90% of the magnets sold and used in today's market. If you are purchasing an item that uses magnets, chances are its either a rare earth or ceramic magnet. So what's the difference and why does it matter?

Strength, durability, size, and the point at which a magnet loses its magnetism when exposed to heat all factor in. Will your magnet need to be used outdoors or exposed to temperature fluctuations? Will it need to have a super strong hold but still be compact and lightweight?

Read on to learn the important differences between the two major groups of permanent magnets and their uses.

Rare Earth Magnets vs. Ceramic Magnets

Ceramic Magnets

Ceramic magnets are the type of magnets you most often encounter in everyday products, toys, and other household items. These magnets are made from a hard ceramic called ferrite. Mainly comprised of iron, ferrite came into use in the 1960s as an inexpensive alternative to aluminum, nickel, and steel magnets and soon dominated the market. One benefit of ferrite is how abundant iron is, making the cost of these magnets very affordable.

The Good

All magnets lose their magnetism if exposed to a high enough level of heat, this is known as the Curie Temperature. Ceramic magnets have a relatively high Curie melting point, approximately 450°C, meaning it takes a temperature of 450°C or above to cause damage to their magnetism. Ceramic magnets are also resistant to corrosion, making them perfect for long-term outdoor use.

The Bad

On the downside, ferrite magnets are heavy, clunky, and inflexible. They can break easily, making them a poor choice for any application that requires flexibility. Ceramic magnets have a comparatively low magnetic field, registering at a mere 3.5 on the (BH)max scale, that's more than a tenth the strength of rare earth magnets. The (BH)max scale registers energy density and it used to measure the strength of magnetic force. The higher the (BH)max the better the magnet. Needless to say, a 3.5 is not a stellar number.

Best Uses

Best uses for ceramic magnets include:

- Power tools that may be exposed to the outdoors for long periods of time

- Automotive industry, particularly DC motors, sensors, and speakers

- Factories that use machines to lift and separate magnetic items

- Educational activities, science class experiments, and homemade crafts

- Home decor and storage

Rare Earth Magnets

Rare earth magnets are named after the strong, rare earth metal alloys they are derived from. First discovered by the U.S. Air Force in 1966, rare earth elements were developed into commercial magnets beginning in the 1970s.

The term "rare earth" can be misleading, as some of these metals are actually quite abundant in the Earth’s crust. Extraction of these metals is a lengthy, complicated process where the raw elements must be purified and isolated from other, less desirable chemical elements. This requires hundreds, sometimes even thousands of steps in the process.

The Good

The incredible strength of rare earth magnets has helped revolutionize the tech industry. Compact and lightweight, these magnets can fit into an iPhone while still packing an enormous magnetic punch. Registering with a magnetic force up to 40 (BH)max, rare earth magnetic are 10 times the strength of ceramic magnets.

There are two types of rare earth magnets, differing in strength and durability: Neodymium magnets and Samarium-Cobalt magnets. Neodymium is more brittle and prone to corrosion but has significant strength – up to 40 (BH)max and are less prone to cracking or chipping.

Samarium Cobalt magnets are more durable but slightly less strong, measuring at 26 to 30 (BH)max. Samarium magnets have incredibly high magnetic stability. They can only be damaged at temperatures above 750°C, making them perfect for applications with exposure to extremely high temperatures.

The Bad

Neodymium have slightly less heat stability than ceramic magnets and begin to lose their magnetism at 310°C, making them less than ideal for high temperatures uses. Their brittleness means they cannot withstand the elements unless coated with stainless steel or a similar alloy cover.

Samarium Cobalt has it all, durability, strength, and the ability to withstand extreme temperatures. However, the extensive manufacturing process required to excavate and make these magnets also makes them incredibly expensive.

Best Uses

Best uses for rare earth magnets include:

- Computer and phone parts

- Wind turbine generators

- Satellites

- Aerospace applications

- Medical equipment, such as MRI scanners

Why Does Banner Stakes Choose Rare Earth Magnets?

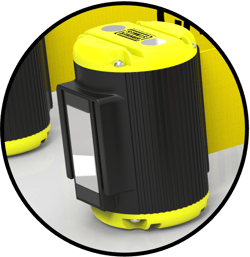

Banner Stakes uses rare earth magnets because of the powerful magnetic force they produce. We take safety seriously, so it's important that our magnetic barriers can attach and adhere to surfaces without falling, breaking, or being easily damaged.

Our use of rare earth magnets makes Banner Stakes' magnetic products unlike any other safety barriers on the market. Other magnetic barriers use 2 to 3 small, round, and far-weaker ceramic magnets. In comparison, Banner Stakes use a large, single rare earth magnet to attach to a greater surface area for a significantly stronger and longer lasting hold.

Banner Stakes Magnetic Line vs. Other Barriers:

Want to learn more about Banner Stakes’ Magnetic Line?